The Box

In this project I explored and learned the basic fundamentals of CAD, tolerances, kerf, and material analysis.

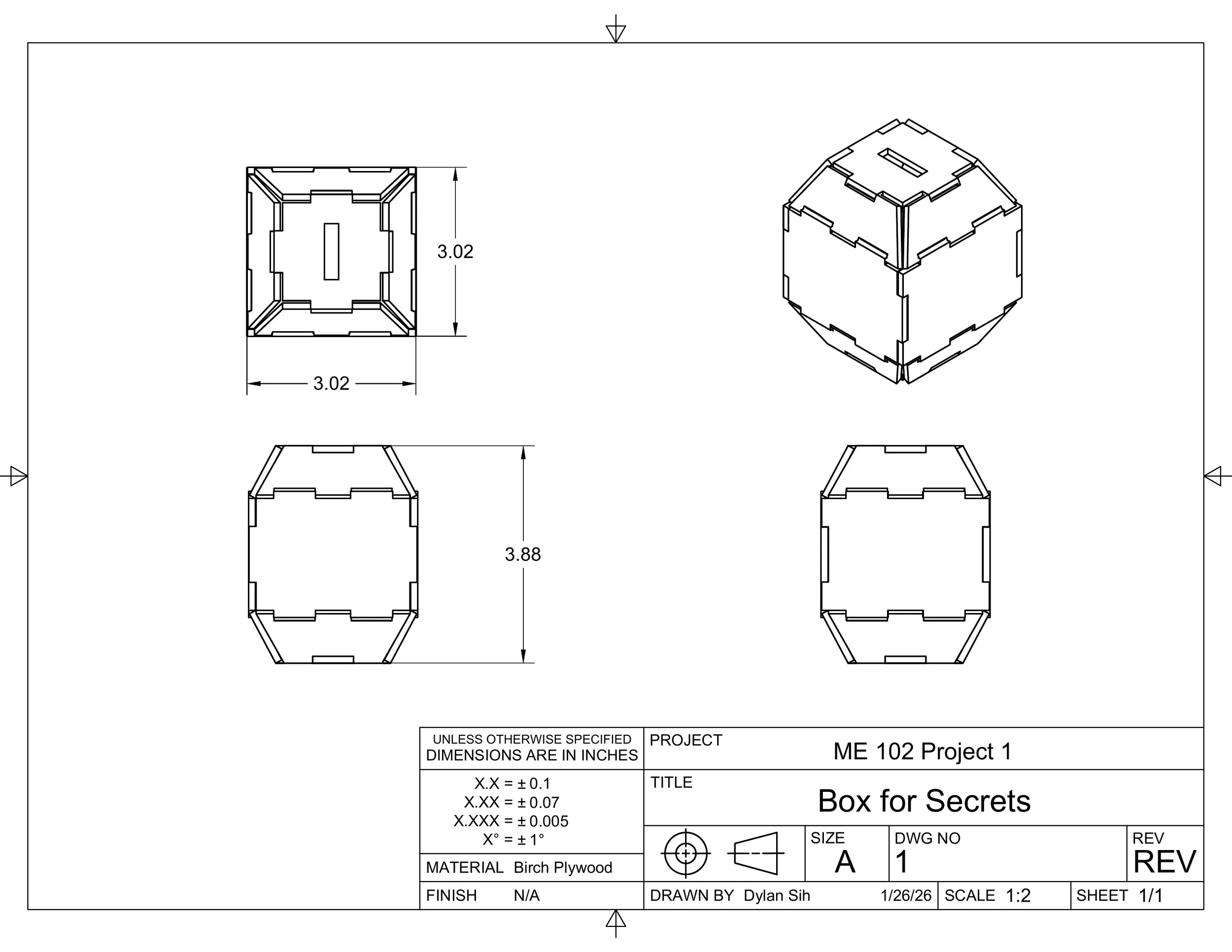

Constraints

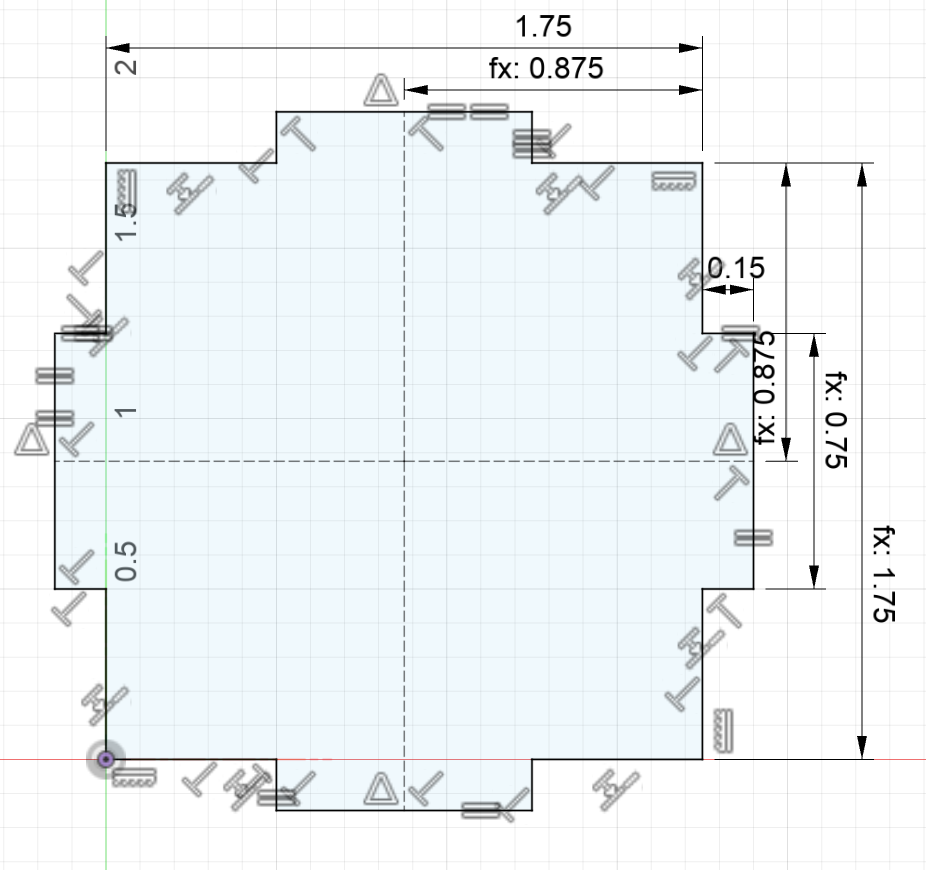

No face orthogonal to all neighbors

No adhesives or fasteners

Material limited to 1 sheet of 12” x 12” birch plywood

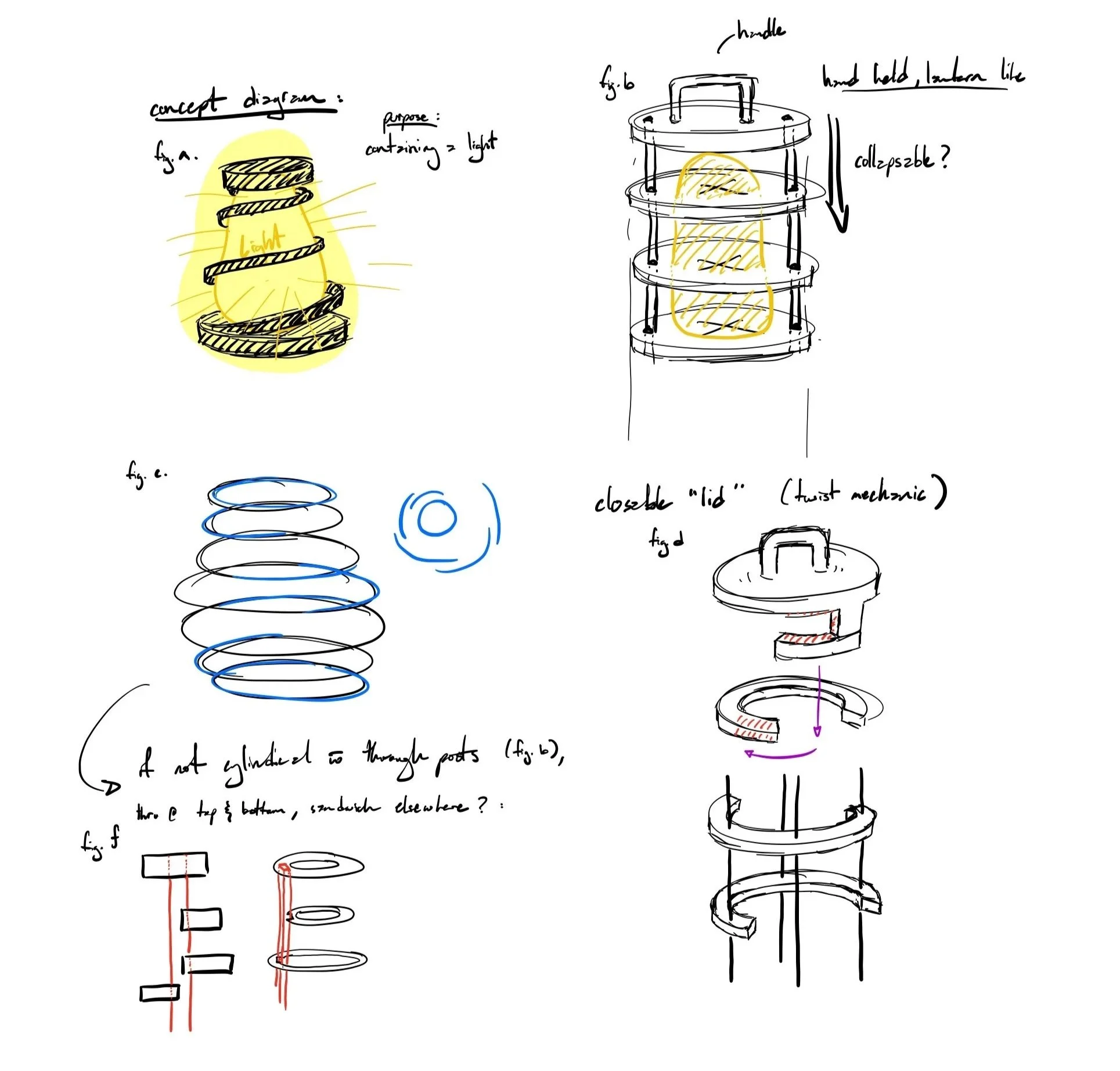

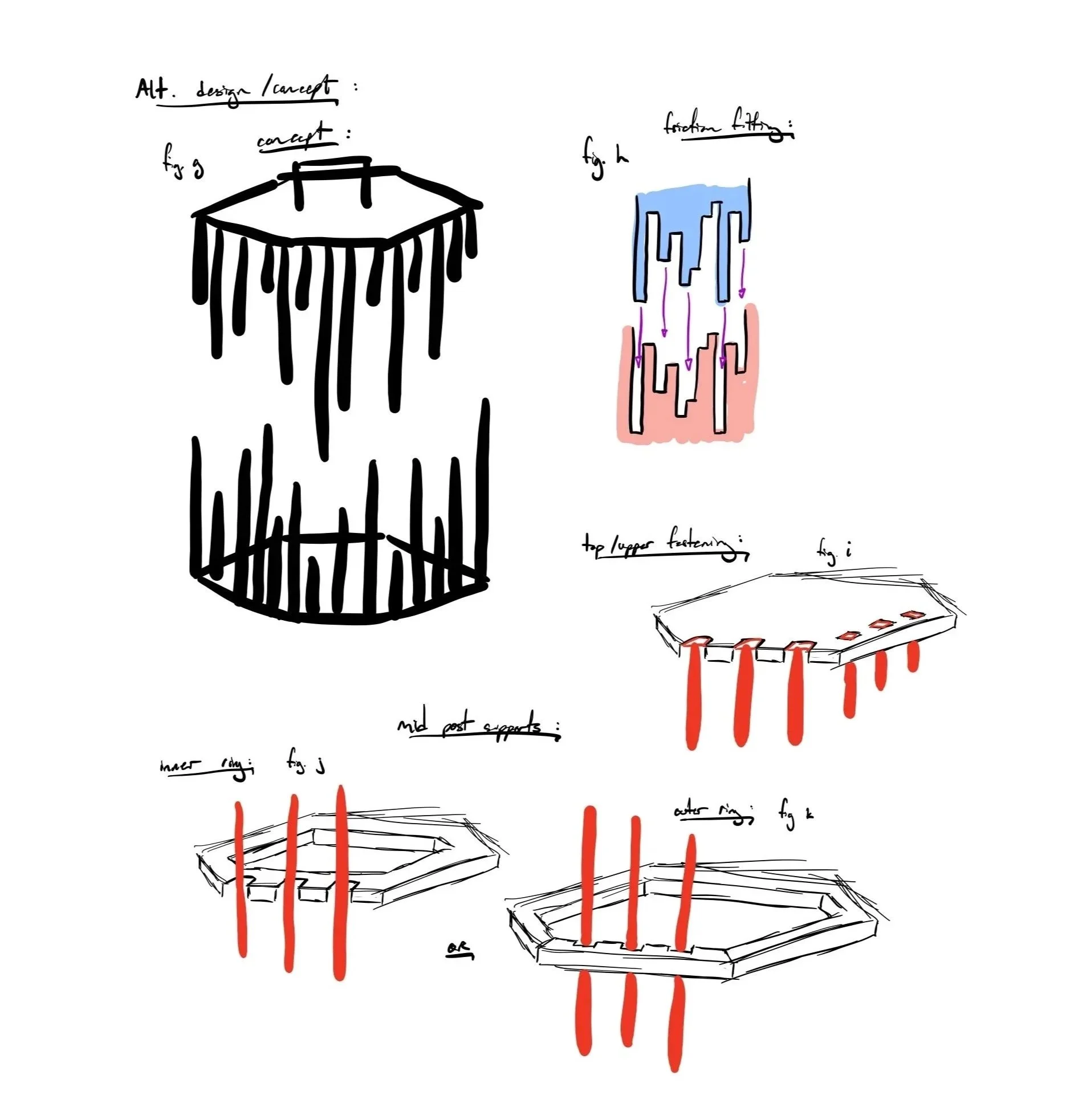

Concept Ideation, Sketches, Prototyping

V1

V1 Rough Prototype

V2

Original Concept Sketches and Prototype Issues:

Too complex (v1 and v2)

Structurally weak (v1)

Did not meet basic specs or orthogonality constraint (v1 and v2

Inefficient use of material (v1)

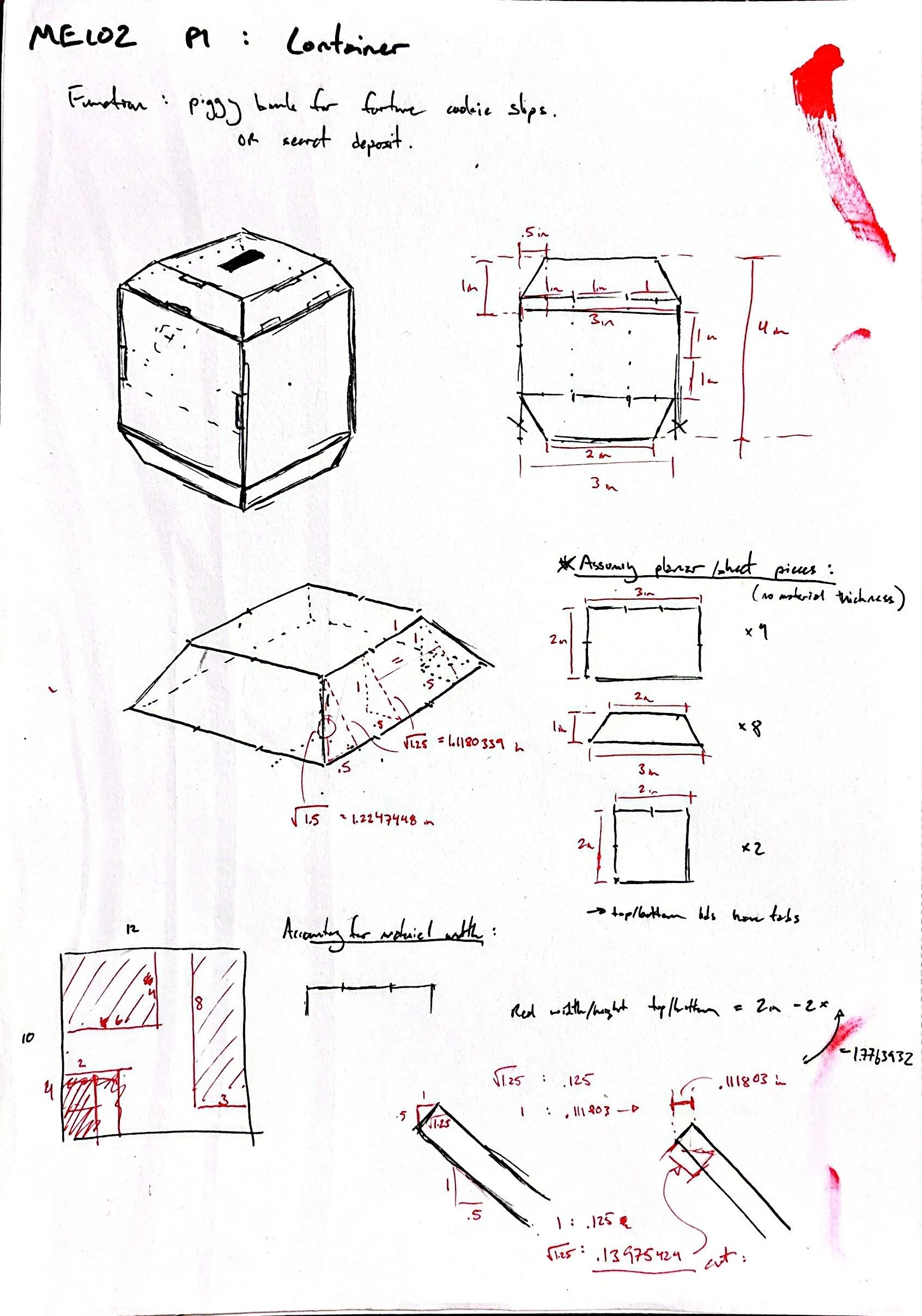

Revised Model Sketches

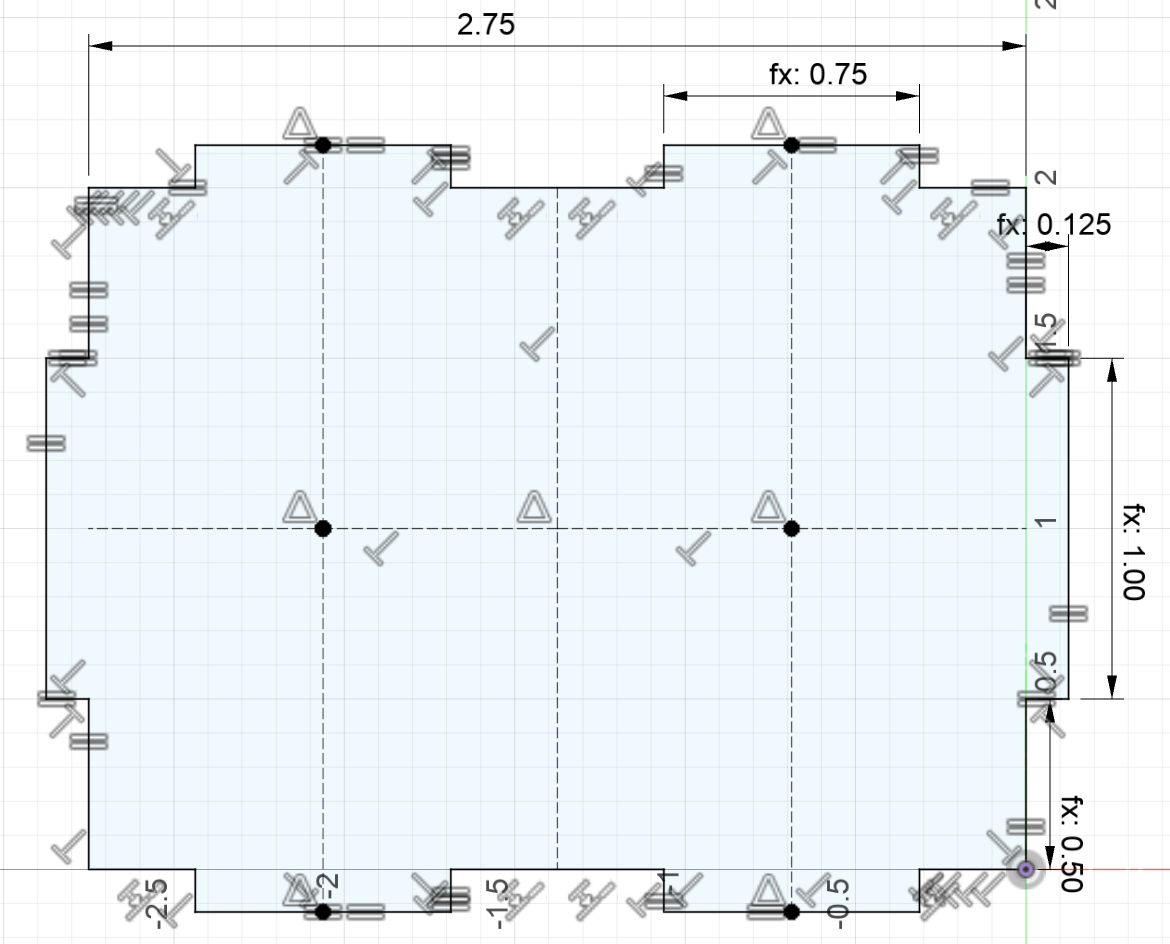

Concept sketched out by hand, then sketched in Fusion 360.

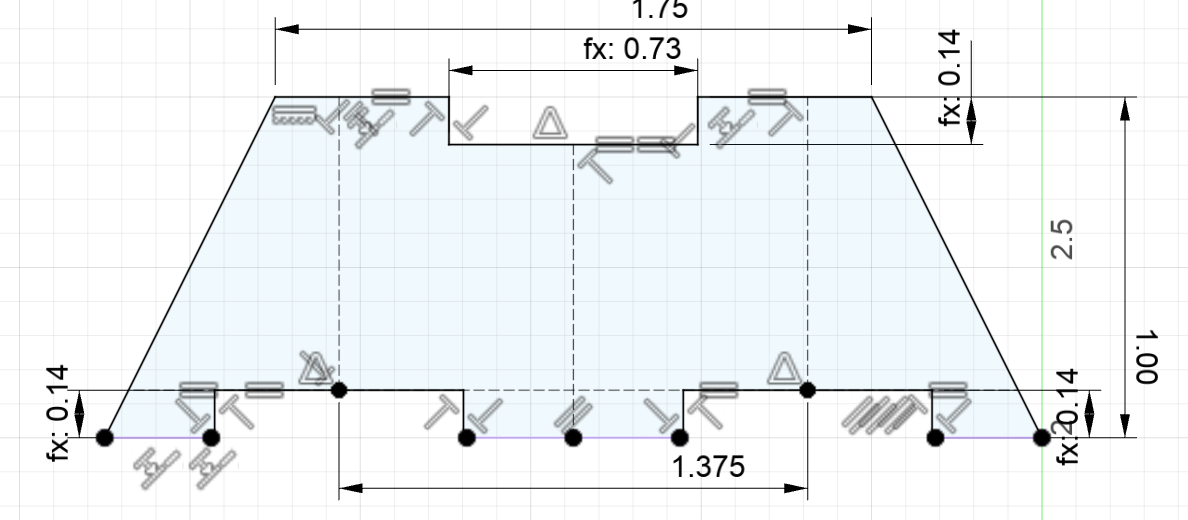

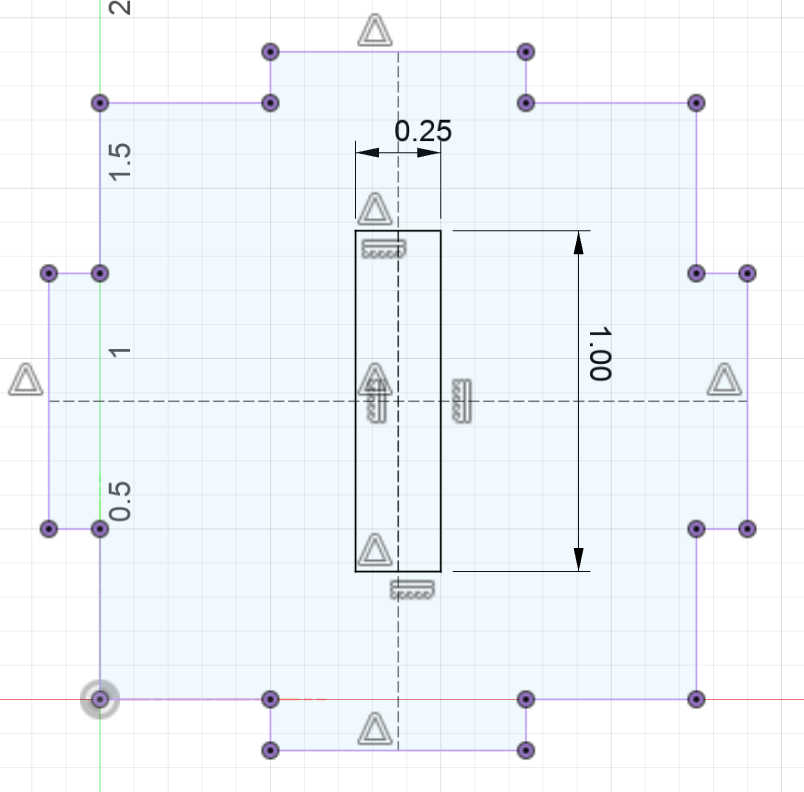

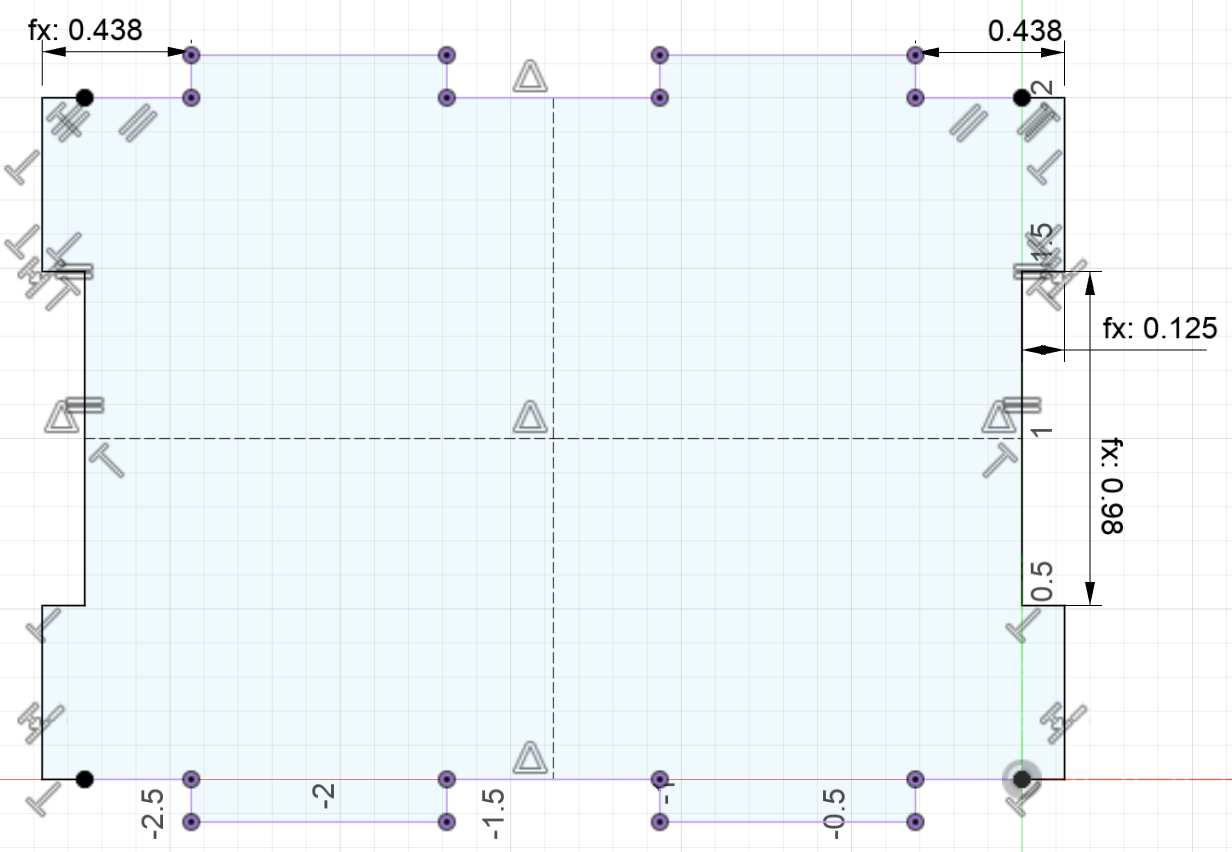

Friction Fits:

Interface/interference in CAD: +.02”

1” tab = .98” hole || .75” tab = .73” hole

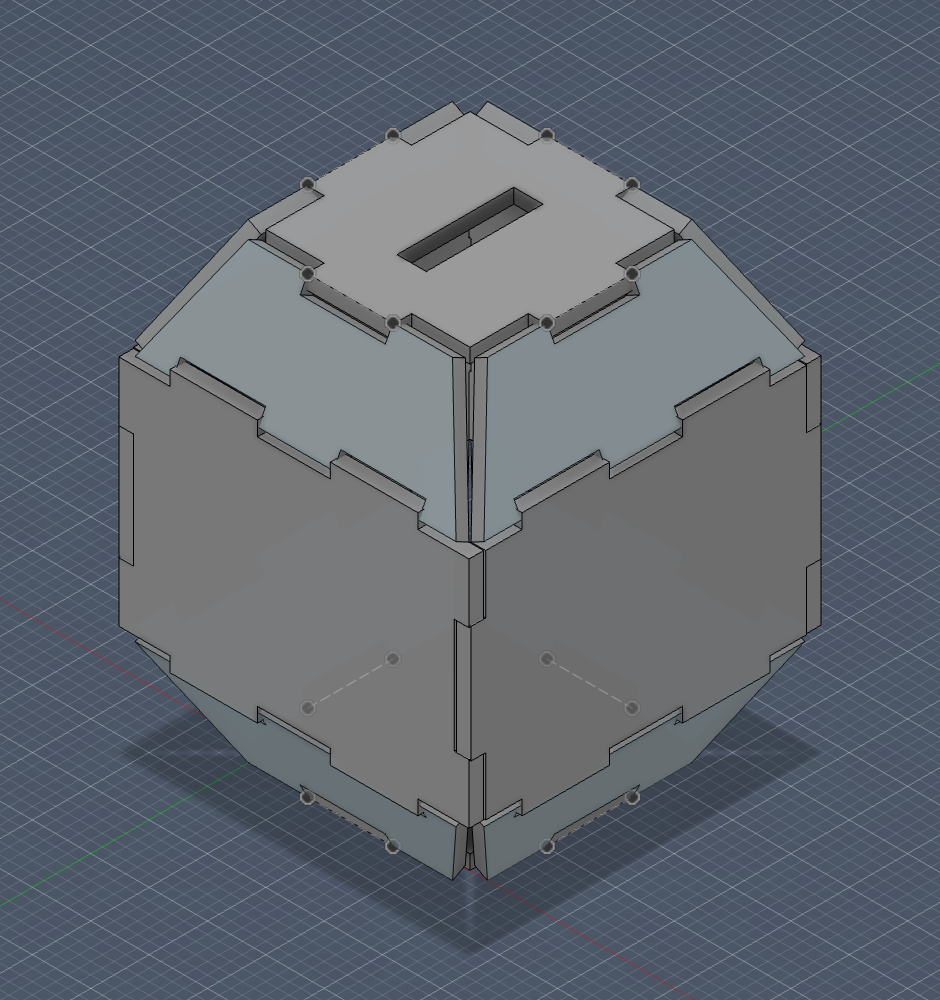

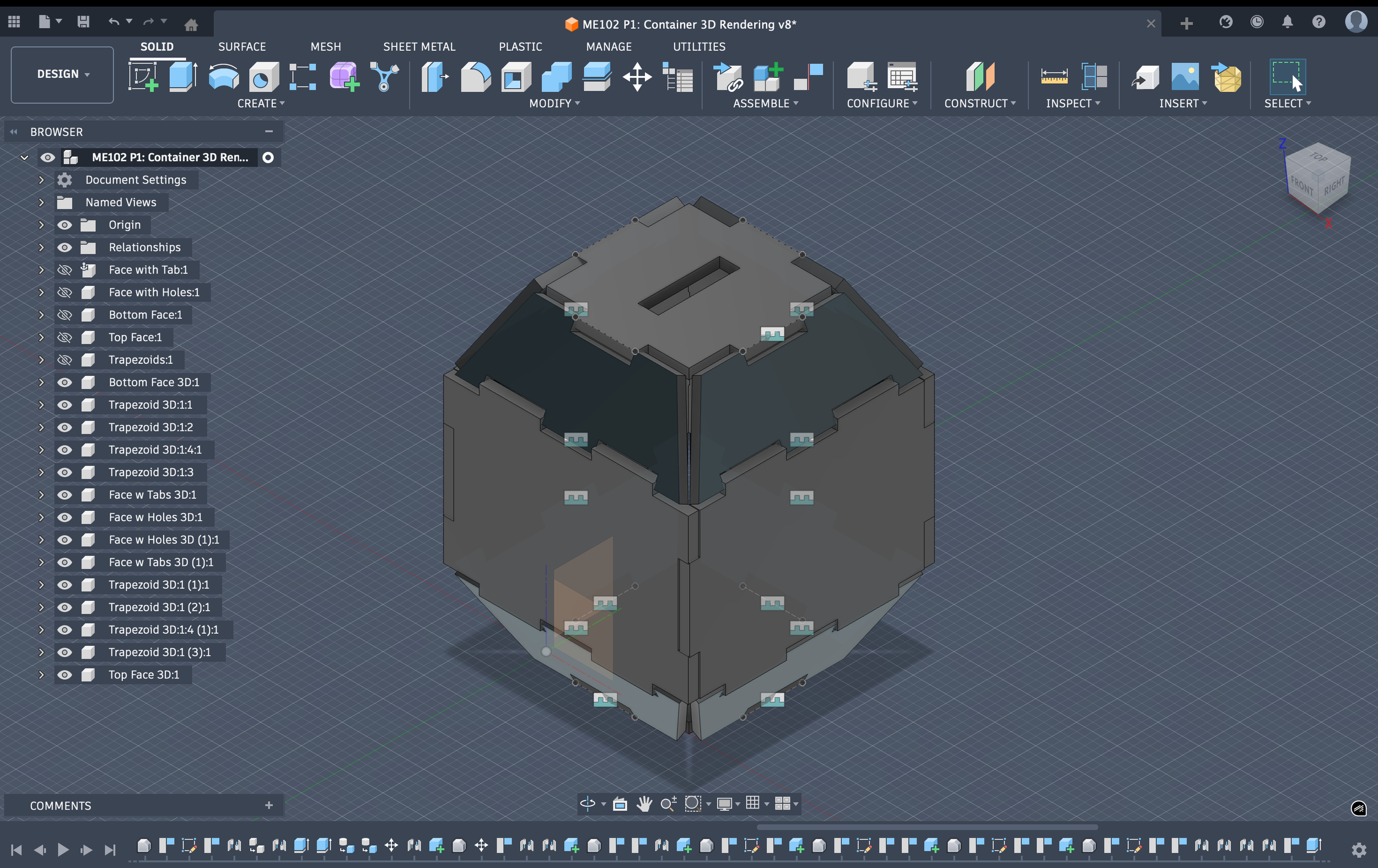

3D CAD Model

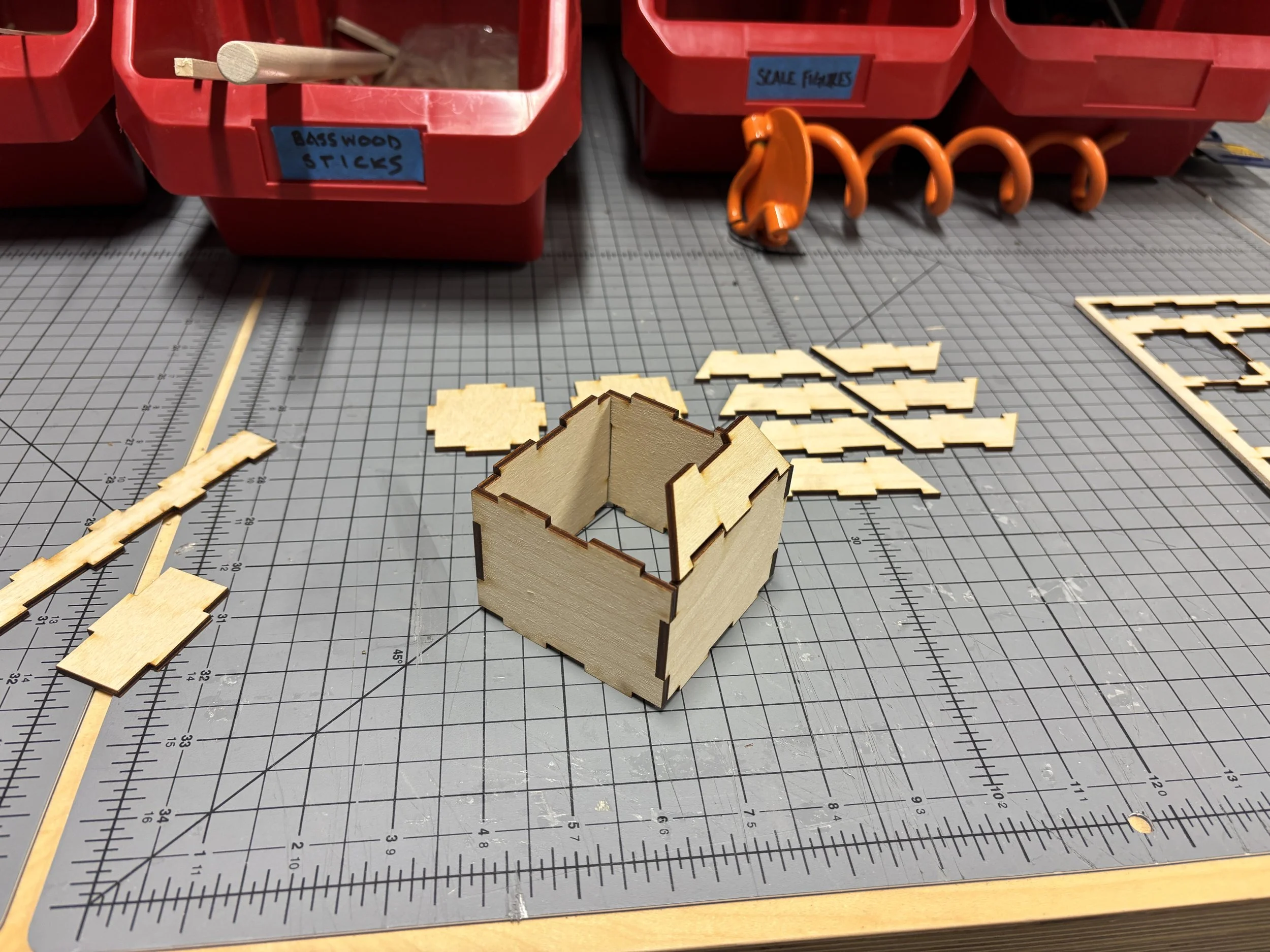

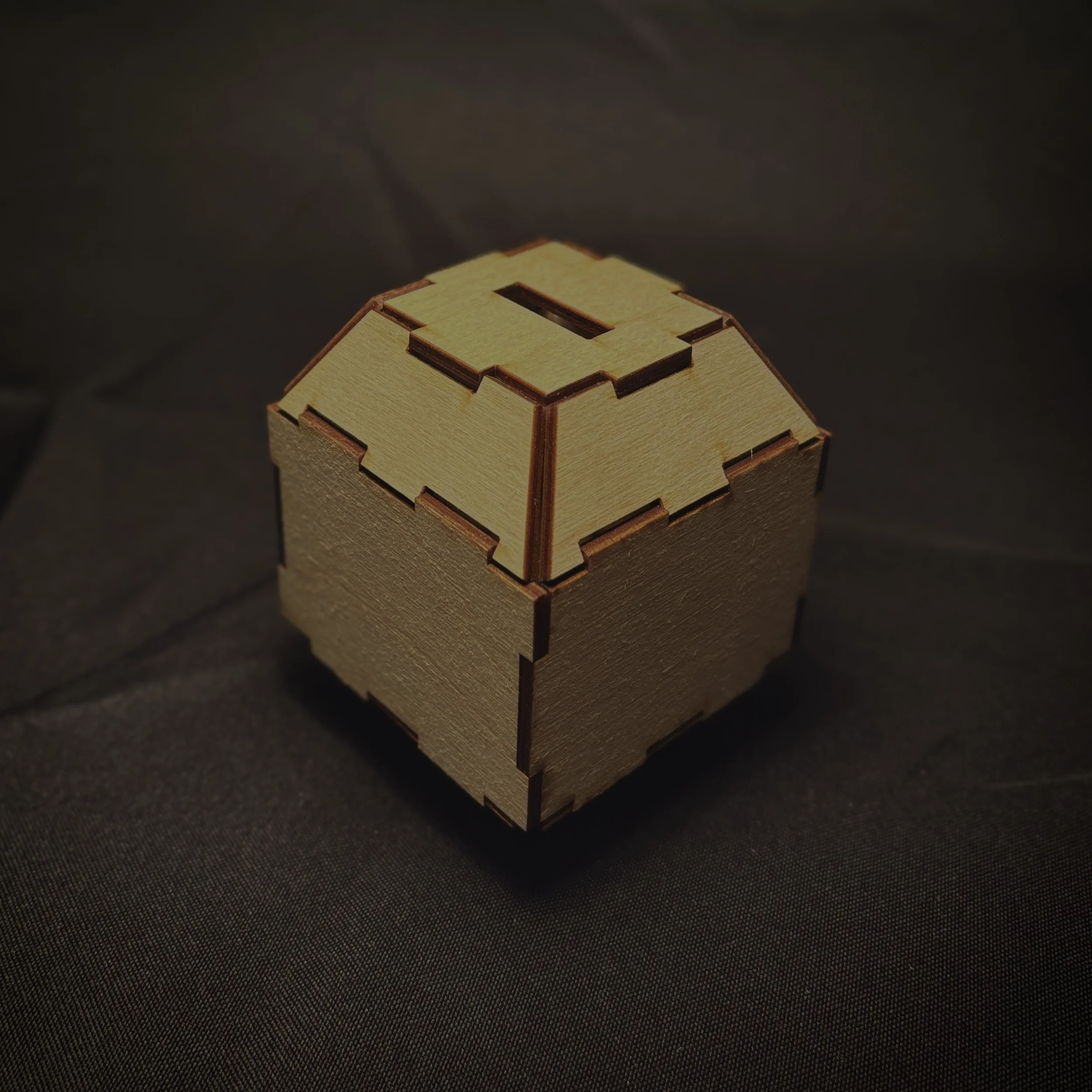

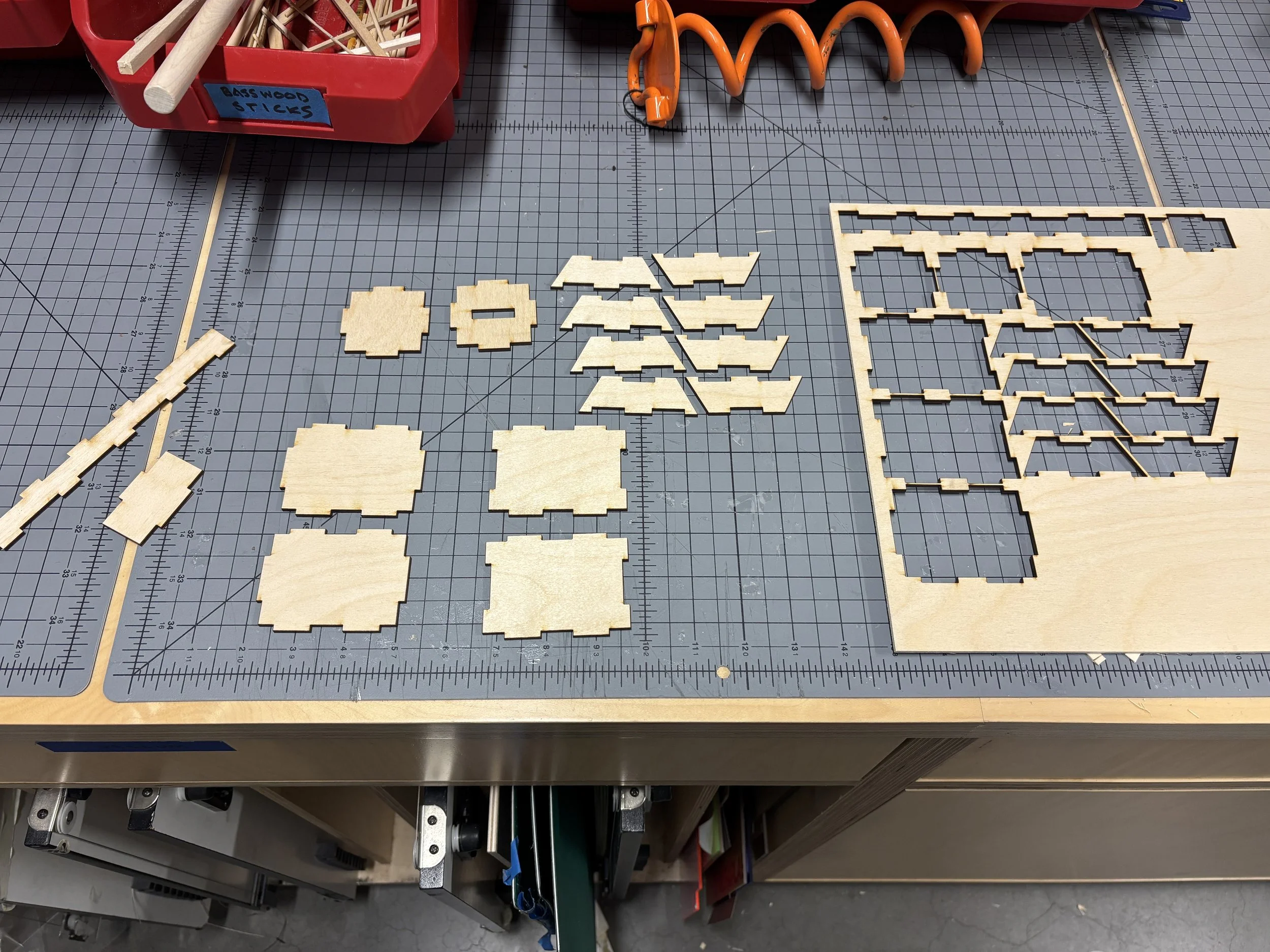

Build Process & Final Model

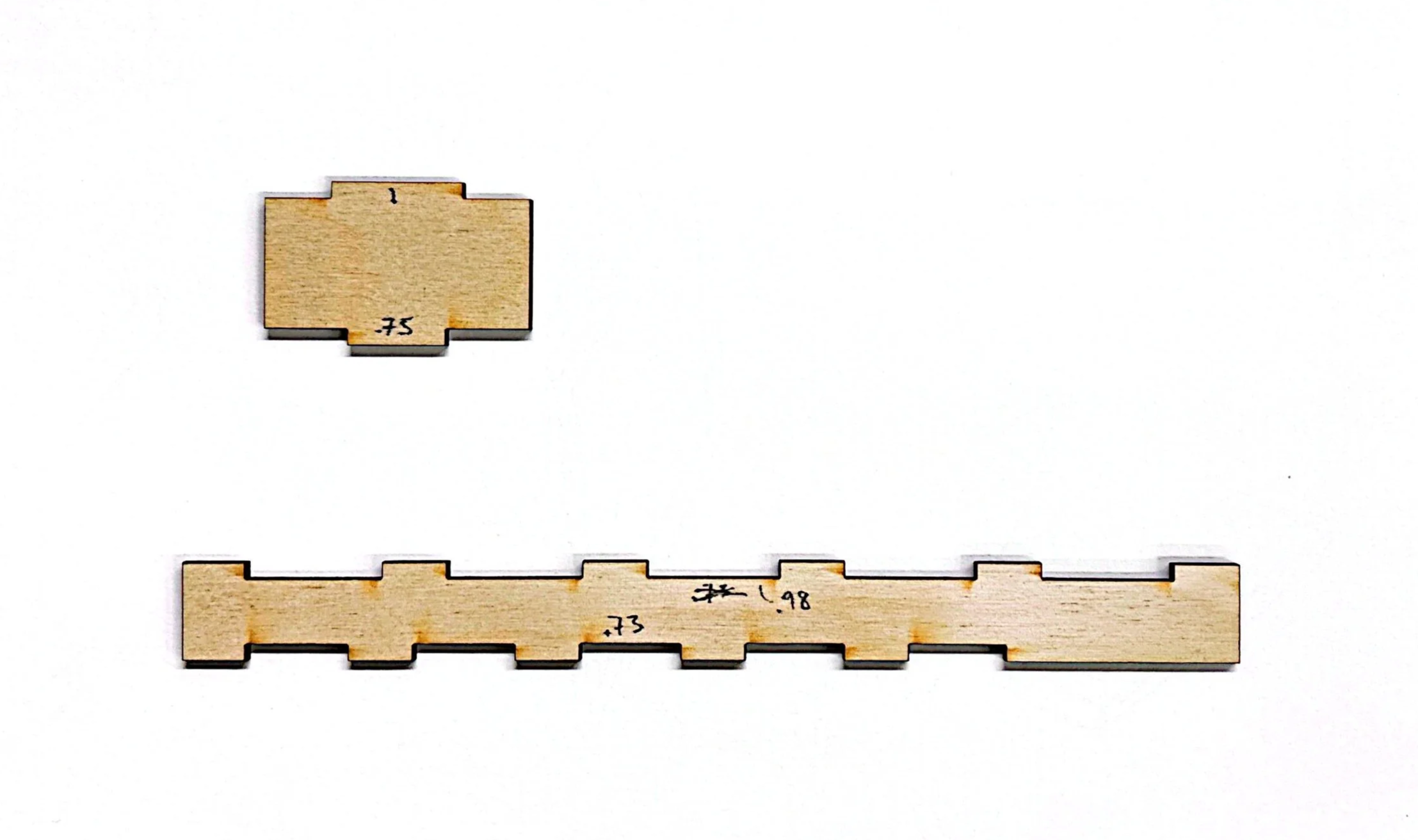

Test cuts:

Tolerance when cut (measured via caliper):

1” → .9850” and .98 → .9830” so: tolerance = +.002”

.75” → .7350” and .73” → .7330” so: tolerance = +.002”